Quality First

With a focus on sustainability, performance, and innovation, Sika Thermoplastic Systems redefine how construction materials are designed and used - supporting a more resilient, circular built environment. Beyond roofing and waterproofing, Sika Thermoplastic Systems power engineered materials such aswaterbars, bituminous membranes, and high-performance fibers for concrete reinforcement.

These solutions are trusted worldwide in infrastructure, construction, and automotive sectors. Our renowned brands include: Sikaproof®, SikaRoof®, Sikaplan®, Sarnafil®, Sikadur Combiflex®, SikaShield®, Sika® Igolflex®, SikaFiber®, SikaTherm®.

Thermoplastic Systems: Engineered Performance, Durability, and Sustainability

Thermoplastic materials have the characteristic ability to transition from a solid to a formable, semi‑fluid state when sufficiently heated. This reversible behavior allows individual components to be joined by applying heat and then solidifying again upon cooling, resulting in homogeneous, continuous structures. Because thermoplastics can be repeatedly softened and reshaped, they offer not only efficient processing during manufacturing but also the advantage of being recyclable and suitable for reuse.

Sika's specially formulated roofing membranes are designed to withstand the everyday occurrence of standing water and other factors such as radiation, pollution, wind, hail, snow, and the growth of biological organisms.

Sika Thermoplastic Systems also support bituminous products, fully bonded membranes, and engineered solutions like waterbars or fibers, which are used in reinforced concrete. Fibers added to concrete during production improve the performance of cracking and fracturing. After many years of research and development, the market now fully accepts fiber reinforcement to improve the performance of concrete and mortar.

During the melt phase of the polymers, special ingredients provide products with their final performance. Processing is one of the key parameters of a quality product. The controlled heating and cooling of thermoplastic material dictates the mechanical properties and longevity of our products.

Sika's Thermoplastic Systems combine waterproofing, reinforcement, and damping solutions. By integrating circular economy principles into roofing, waterproofing, concrete, and automotive applications, we create innovations . from durable roofing membranes to advanced automotive materials - that shape the future of sustainable construction and mobility." Christoph Fäh, Head of Technology Thermoplastics

Comprehensive Solutions

Sika is committed to sustainability through innovative recycling

solutions for roofing membranes. By enabling material recovery and reuse, we support a circular economy that minimizes waste and reduces environmental impact. Our advanced recycling technologies transform end-of-life membranes into valuable resources for new products, closing the loop in roofing systems.

Sika’s fully bonded membrane portfolio is built around its SikaProof® technologies, including pre‑applied FPO sheet membranes such as SikaProof® A+ and post‑applied systems like SikaProof® P, which create a permanent mechanical and adhesive bond to concrete and prevent lateral water migration. These systems use advanced TPO/FPO membrane technology with integrated sealant grids and non‑woven fleece backings to deliver high flexibility, crack‑bridging performance, and reliable waterproofing for below‑grade structures.

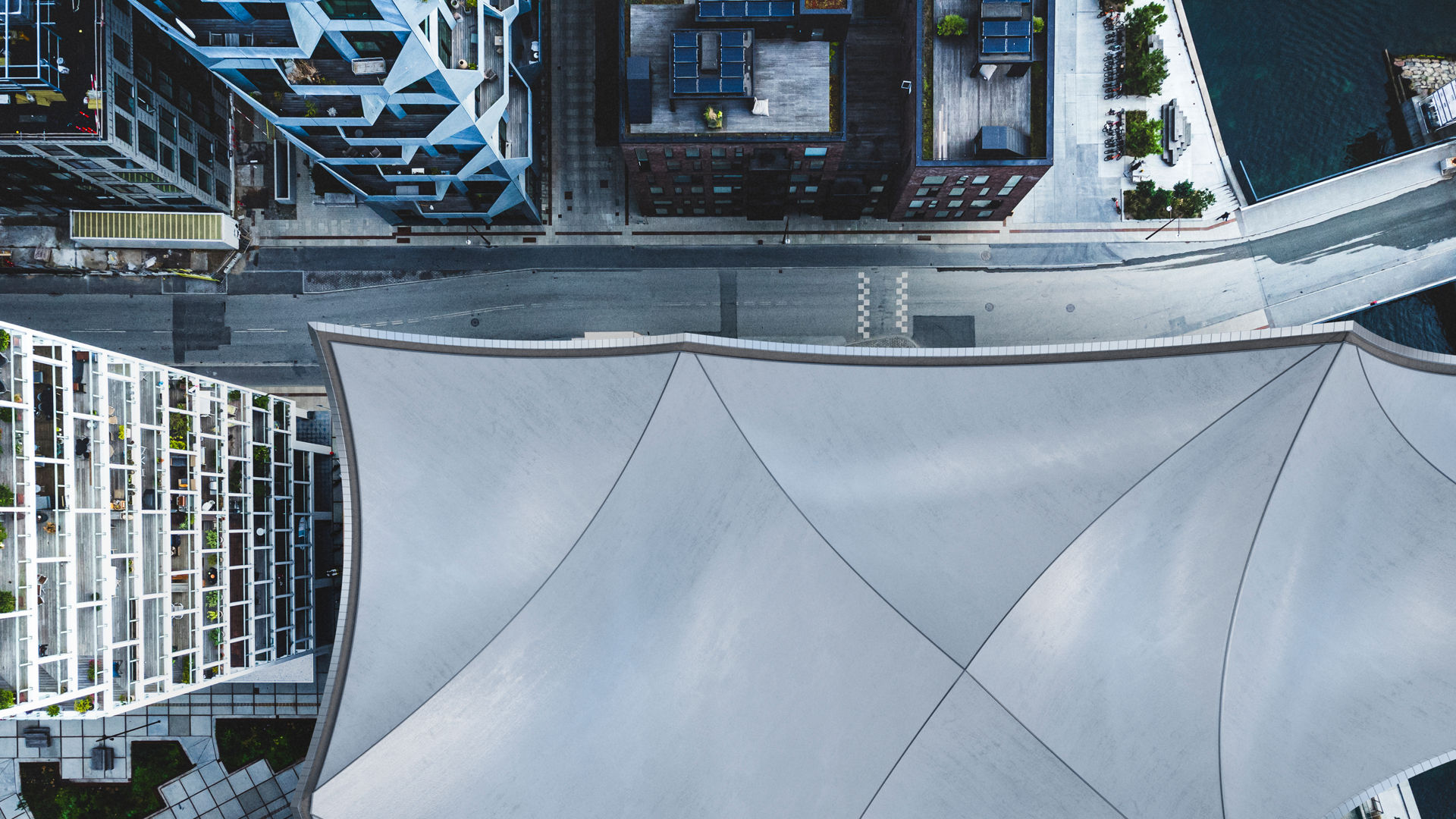

Sika’s single-ply roofing systems combine cutting-edge thermoplastic technology with proven durability. Whether Sarnafil® AT, SikaRoof® AT or SikaPlan® membranes on polymeric basis deliver superior resistance to UV radiation, standing water, and extreme weather conditions. Designed for energy efficiency and long service life, our systems set the benchmark for sustainable roofing worldwide.

Fiber-reinforced concrete is a cornerstone of modern construction. Sika’s high-performance fibers improve crack resistance, enhance structural integrity, and extend the lifespan of concrete structures. From tunnels to high-rise buildings, our fiber solutions ensure reliability in the most demanding environments.

By integrating thermoplastic modifiers into bituminous membranes, Sika elevates performance standards for waterproofing and roofing applications. These enhancements deliver improved flexibility, weather resistance, and longevity, ensuring robust protection for infrastructure and buildings.

Sika’s thermoplastic innovations drive progress in the automotive industry. Our lightweight, high-strength materials enable manufacturers to reduce vehicle weight without compromising safety or performance. The result: improved fuel efficiency, lower emissions, and advanced design possibilities for next-generation mobility.

Sika offers a comprehensive range of thermoplastic compounds and filaments for additive manufacturing, combining decades of material expertise with solutions tailored for industrial 3D printing. The SikaBiresin® TP portfolio includes PP, PE, PVC, TPO, EVA, and specialty grades, available in flexible to stiff formulations with options for flame retardancy, UV protection, water resistance, and color customization. Designed for reliable printability, durability, and long-term performance, these materials support applications from prototyping and mold making to series production. Customer-specific compounding further enables precise material solutions aligned with individual application needs, with sustainability and longevity at the core of Sika’s offering.