08/11/2021

Sika has joined Alumobility, a non-profit organization focused on proven innovative solutions to advance the adoption of aluminum automotive body sheet, as new member. Together with experts in a variety of joining techniques for aluminum and other metals, Sika will contribute know-how in bonding, sealing, damping and reinforcing for car body structures and components.

Collaboration With Alumobility Follows Customer First Approach

“We are thrilled to welcome ARO, Atlas Copco and Sika to Alumobility,” said Mark White, Executive Director of Alumobility. “Their expertise in welding, self-pierce riveting, flow drill fastening, adhesive bonding and other joining methods will demonstrate reliable, efficient and cost-competitive manufacturing solutions for aluminum automotive body structures and components. By working together, aluminum producers and downstream providers can help automakers reap the benefits of light, strong, sustainable aluminum.”

Urs Jaeger, Head R&D Automotive Technologies at Sika: “For Sika, collaboration and innovation belong together, that’s why we have become a member of Alumobility. Sika complements its own research efforts by working with major universities and scientific institutes on fundamental technologies. The partnership with this innovative association and its members contributes to strengthen strategic intelligence, in-depth knowledge and insight as well as foresight into what is going to advance the adoption of aluminum in car body construction all over the world, in order to build lighter and safer cars. At the end, our customers will benefit from this expertise. That’s our ambition.”

Pascal Obringer, Head Global Sales Support, Sika Automotive AG: “The partnership with Alumobility and the collaboration with technology partners has been initiated in the context of the Sika customer first approach: Sika's wide-ranging solution-set gives us the ability to support customers in multiple areas of their manufacturing processes, and provides insight into their broader challenges. The work with Alumobility aims to process collaborative technical projects and to foster knowledge management. This will have a positive impact on fulfilling the promise of a lighter, more efficient, more sustainable mobility future.”

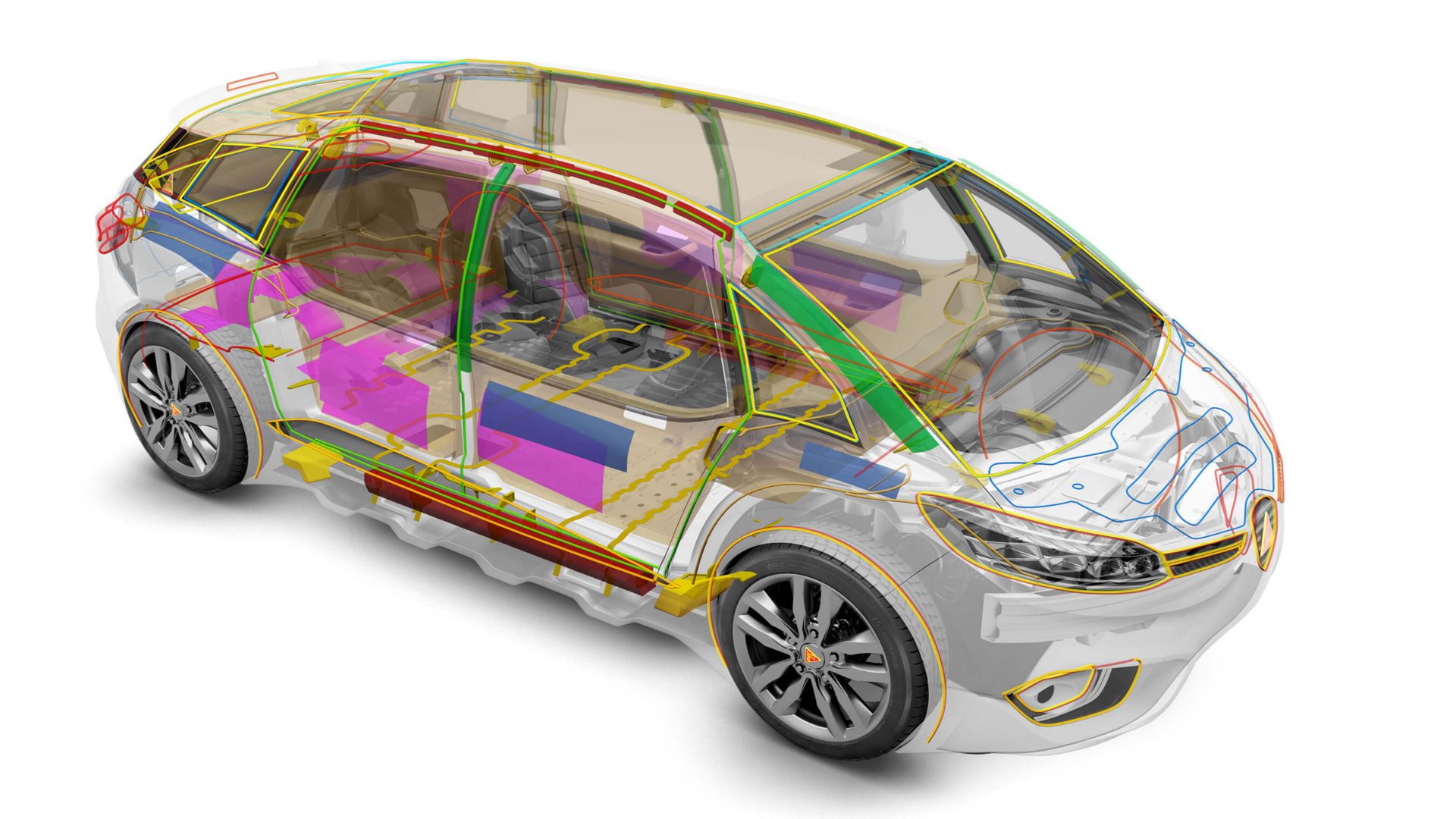

The use of aluminum in the car body is an efficient way to reduce vehicle weight and thereby to realize better fuel efficiency and significant reduction of CO2 emissions. The Alumobility partners are performing collaborative technical projects investigating and advancing the capabilities of aluminum in car body construction providing innovative implementation-ready solutions. Structural and crash resistant bonding with SikaPower® body shop adhesives has become a major technology for joining car body components. The technology is even more important when using instead of steel lighter but also less rigid aluminum.

Most modern high-performance car bodies consist of a mix of many different steel and aluminum grades, in some cases also plastic composite materials, therefore, to realize such a mixed material construction adhesive bonding is inevitable. To stiffen aluminum structures the use of Sika's structural insert technology SikaReinforcer® is very beneficial..

About Alumobility

Launched in January 2021, Alumobility conducts collaborative technical projects to help automakers utilize aluminum automotive body sheet to fulfill the promise of a lighter, more efficient, more sustainable mobility future. The association combines a global ecosystem of leading aluminum and downstream technology partners that supports automotive manufacturers in creating lighter, safer, smarter and more sustainable vehicles. The non-profit association was founded to focus on proven technical solutions to advance the adoption of aluminum automotive body sheet (ABS). Working with global automakers, Alumobility will help fulfill the promise of a lighter, more efficient, more sustainable mobility future.